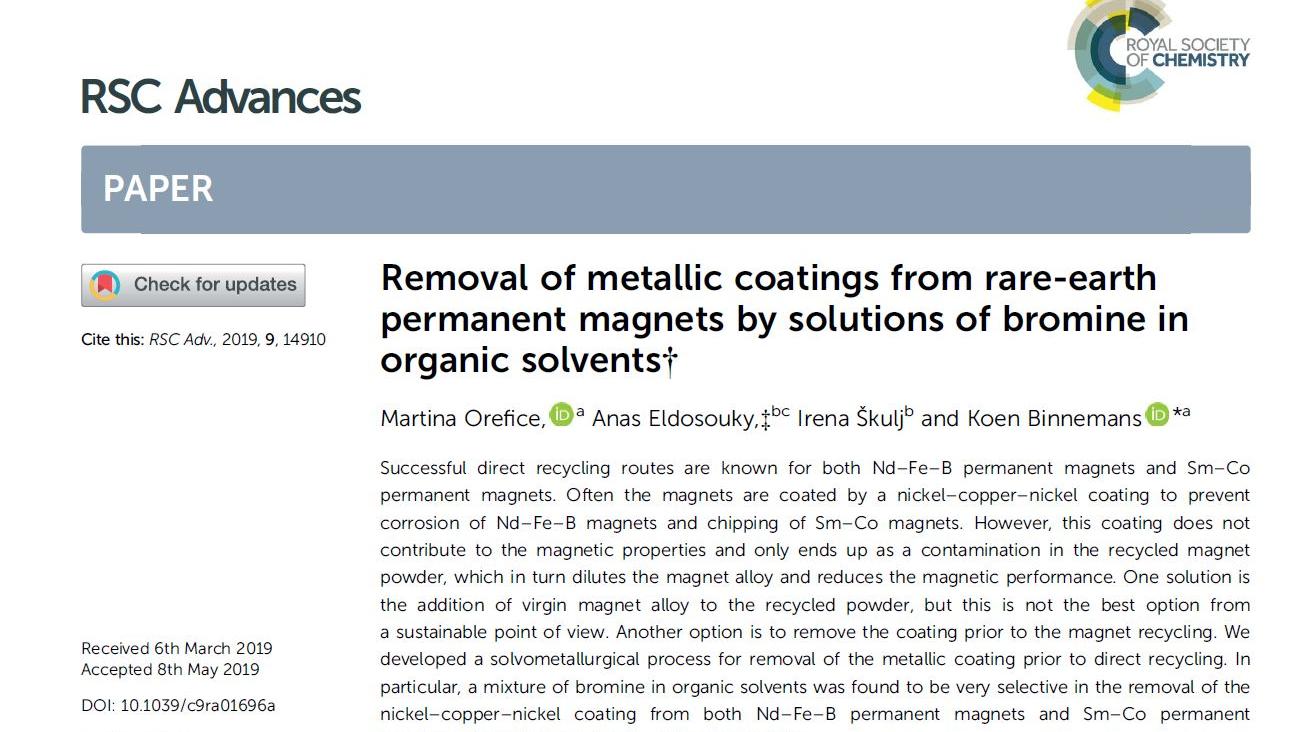

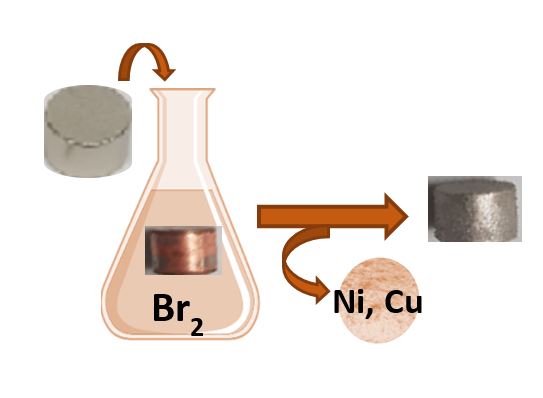

Rare-earths permanent magnets were treated with solvometallurgical solutions of Br2 in organic solvents to remove the Ni-Cu-Ni coating prior to direct recycling. A comparison with 2 M HNO3 treatment proved the advantages of the solvometallurgical process. The work is published in ChemElectroChem. (MO/LAO, Leuven, 28/05/2019)

Successful direct recycling routes, mainly via hydrogen decrepitation, are known for both Nd‒Fe‒B permanent magnets and Sm‒Co permanent magnets. Often the magnets are coated by a nickel-copper-nickel coating to prevent corrosion of Nd‒Fe‒B magnets and chipping of Sm‒Co magnets. However, this coating does not contribute to the magnetic properties and only ends up as a contamination in the recycled magnet powder, reducing the performance of the secondary-produced magnet. We developed a solvometallurgical process for removal of the metallic coating prior to the direct recycling. In particular, mixtures of bromine in different organic solvents (DMF, EG, EtOAc, EtOH, MeOAc) were tested on both Nd‒Fe‒B Sm‒Co bulk permanent magnets. The solvents were chosen according to their polarity and their Gutmann donor’s number (which measures the solvation capability of a solvent). Viscosity also showed to have a relevant influence on the magnet coating removal. The best performing mixtures were bromine in EtOH and in DMF, but EtOH has to be preferred since DMF is not a green solvent. A comparison with 2 M HNO3 treatment proved the advantages of the solvometallurgical bromine-based process in the removal of the nickel-copper-nickel coating from both Nd‒Fe‒ and Sm‒Co permanent magnets, without codissolution of the magnet alloy.

Biography Martina Orefice

Martina Orefice graduated in Environmental Sciences (BSc) in 2010 and in Chemical Engineering (BEng) in 2012 and (MEng) in 2015 at the University Federico II of Naples (Italy), her birth-city. Passionate for environmental issues thanks to a board game in her childhood, Martina aims to be a professional in secondary raw materials and circular economy.

Martina Orefice graduated in Environmental Sciences (BSc) in 2010 and in Chemical Engineering (BEng) in 2012 and (MEng) in 2015 at the University Federico II of Naples (Italy), her birth-city. Passionate for environmental issues thanks to a board game in her childhood, Martina aims to be a professional in secondary raw materials and circular economy.

Acknowledgements

The research leading to these results received funding from the European Community’s Horizon 2020 Programme ([H2020/2014-2019]) under Grant Agreement no. 674973 (MSCA-ETN DEMETER). This publication reflects only the authors’ view, exempting the Community from any liability.