Rechargeable batteries with magnesium metal anodes (RMBs) have since long been regarded as a promising post-Li-ion technology. However, their breakthrough has been impeded by passivation issues associated with the magnesium anode. In view of meeting this challenge, SIM² KU Leuven researchers have successfully deposited and stripped magnesium metal with high reversibility from molten mixtures of solvate ionic liquids (SILs) and tetrabutylammonium chloride (TBACl) at 80 °C. High current densities in excess of 1 A dm-2 were achieved during electrodeposition and the influence of chloride concentration of this process was studied. This SIM² KU Leuven work was published in the open access journal RSC Advances.

Magnesium vs. lithium

The lithium-ion battery technology has reached maturity and was rewarded with the Nobel prize of Chemistry 2019 because of its strong impact on our current society by enabling the development of portable electronic devices and electric/hybrid vehicles.

However, concerns about the sustainability of lithium-based battery chemistries are increasing, especially for applications where high energy densities and energy storage capacities are important.

Rechargeable batteries with magnesium metal anodes have since long been regarded as a promising post-Li-ion technology that can mitigate these issues. Apart from allowing higher energy densities, magnesium metal is also environmentally-benign, non-toxic, and much safer, abundant and cheaper with respect to lithium metal anodes.

Challenges in the development of rechargeable magnesium batteries (RMBs)

The main roadblock in the development of RMBs is the high sensitivity of the magnesium anode for passivation due to parasitic side reactions with electrolyte components or trace impurities. Currently, reversible magnesium deposition/stripping is only possible in electrolytes based on volatile ether solvents, which pose environmental and safety risks.

Solvate ionic liquids (SILs) as electrolytes for magnesium deposition

SILs are ionic liquids (ILs) that consist of a solvated metal cation and a weakly coordinating anion. Because the metal is part of the IL structure, very high concentrations can be achieved, resulting in high current densities during electrodeposition.

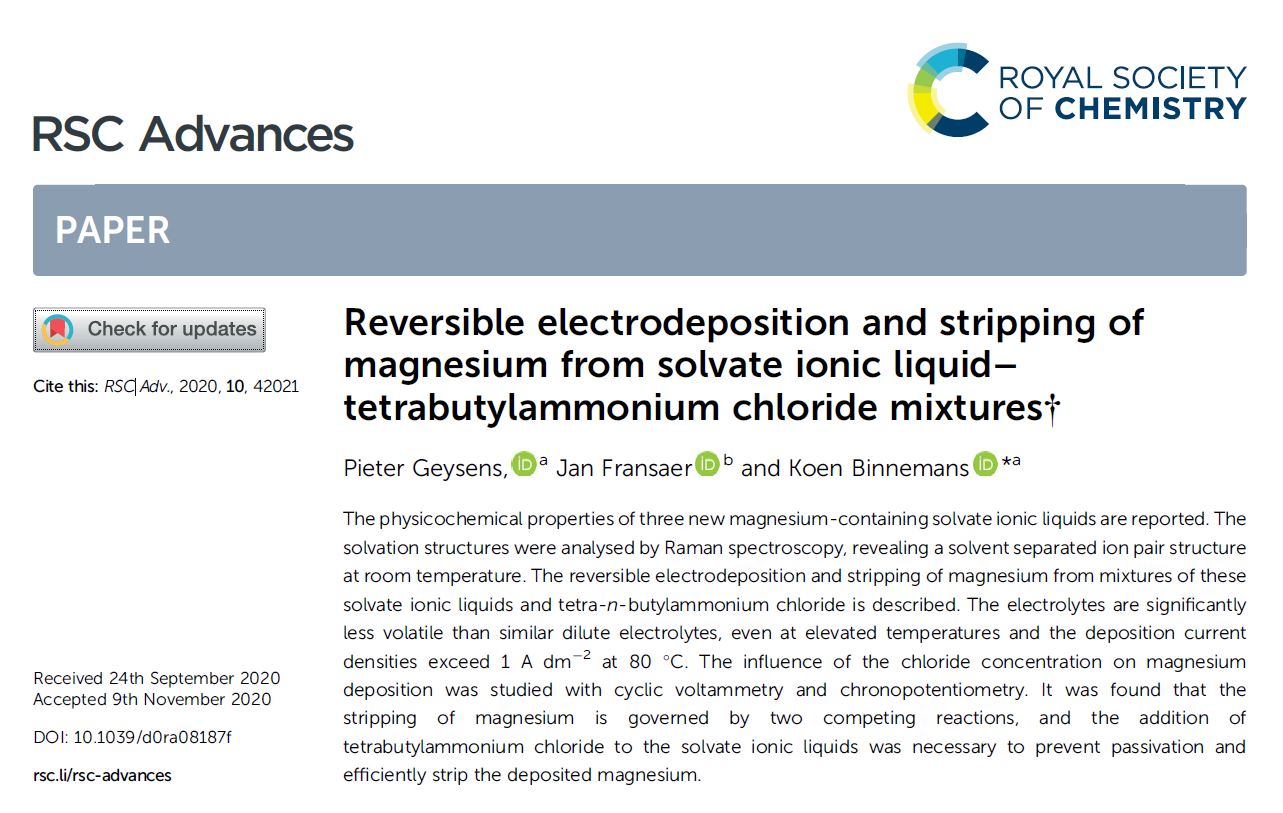

In this SIM² KU Leuven paper by researchers from SOLVOMET (Dept. of Chemistry) and SIEM (Dept. of Materials Engineering), magnesium-containing SILs ([Mg(G)n)][Tf2N]2; n = 1-3; G = glyme) were used as less-volatile electrolytes for the reversible electrodeposition/stripping of magnesium metal at 80 °C. It was found that the pure SILs were suitable for the electrodeposition of magnesium, but stripping was only achieved at high overpotentials and the reversibility was poor.

In order to reduce the overpotential for magnesium stripping, the organic chloride salt tetra-n-butylammonium chloride (TBACl) was added in various molar ratios to the SIL, and this was found to significantly enhance the reversibility of the process.

The presence of metallic magnesium in the deposits was confirmed by energy-dispersive X-ray spectroscopy (EDX) and powder X-ray diffraction (XRD).

Full reference paper

P. Geysens, J. Fransaer, K. Binnemans, Reversible electrodeposition and stripping of magnesium from solvate ionic liquid‒tetrabutylammonium chloride mixtures, RSC Adv. 10 (2020), 42021‒42029. DOI: 10.1039/d0ra08187f

Acknowledgements

The authors thank the KU Leuven for financial support (project KP/14/005). The research was supported by the European Research Council (ERC) under the European Union's Horizon 2020 Research and Innovation Programme: Grant Agreement 694078 – Solvometallurgy for critical metals (SOLCRIMET).

About the SOLVOMET Group

The dual mission of the SOLVOMET Group, led by Prof. Koen Binnemans (ERC Advanced Grant Holder – SOLCRIMET), is (1) to perform excellent research in metallurgical chemistry and to educate and train young researchers in this domain and (2) to support its (industrial and RTD) partners in the conceptual and practical development of more sustainable solvometallurgical (and hydrometallurgical) separation processes and new mining chemicals, which are subsequently tested using state-of-the-art lab-scale and mini-pilot-scale experimental facilities.