Welcome to

SOLVOMET

SOLVOMET is KU Leuven’s Research and Innovation Centre for Circular Hydrometallurgy. We support mining, metallurgical and recycling companies in the development of more sustainable (circular, low-energy input) hydrometallurgical processes, using state-of-the-art lab and mini-pilot scale experimental facilities and modelling capabilities.

SOLVOMET’s vision is that metallurgical chemistry expertise allows to develop more efficient eco-friendly hydrometallurgical and solvometallurgical processes to provide the critical metals that are needed for the transition to a climate-neutral society.

SOLVOMET’s mission is to support its industry partners in the conceptual and practical development of more sustainable (circular, low-energy input) hydrometallurgical (and solvometallurgical) processes, which are subsequently tested using state-of-the-art lab-scale and mini-pilot-scale experimental facilities.

Circular Hydrometallurgy

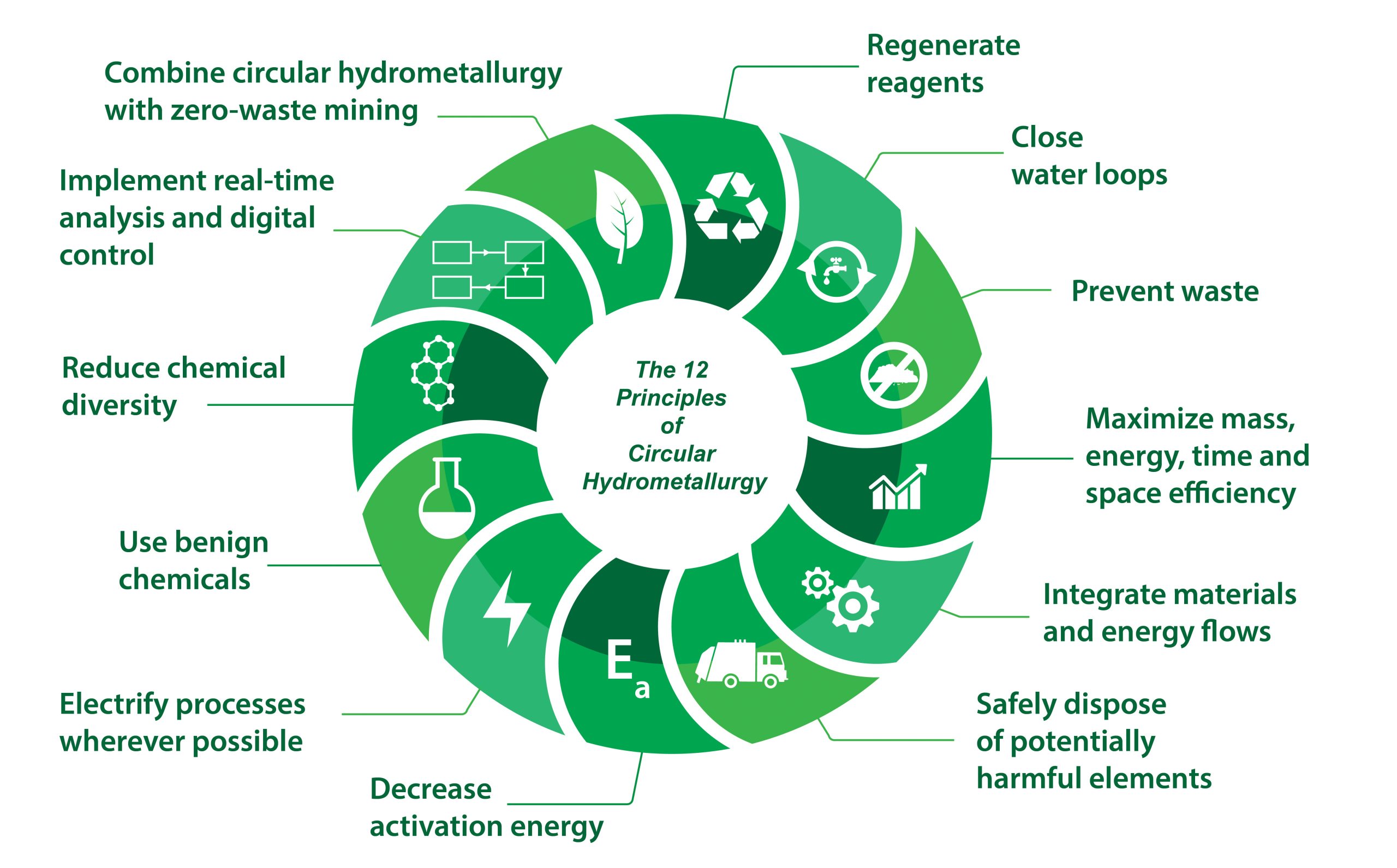

Genuine breakthroughs in hydrometallurgy will not come from the use of neoteric solvents like ionic liquids or deep-eutectic solvents, but rather from a deep understanding of hydro-processes at a molecular level. Hydrometallurgy needs to evolve to low-energy-input circular hydrometallurgy.

Circular hydrometallurgy is the area of hydrometallurgy that focuses on the design of energy-efficient flowsheets or unit processes that consume a minimal amount of reagents and produce virtually no waste. It entails a different way of thinking about how hydrometallurgy is practiced, both for primary mining and recycling processes. Circularity refers to the regeneration and reuse of all the reagents in a process.

Our main expertise

- Chemical and mineralogical characterisation of metal-bearing ores, concentrates, tailings, industrial process residues and postconsumer waste

- Development of eco-friendly hydrometallurgical unit processes for metal recovery (advanced leaching) and purification (solvent extraction, ion exchange…)

- Development of (near-circular, low-energy-input) hydrometallurgical flowsheets

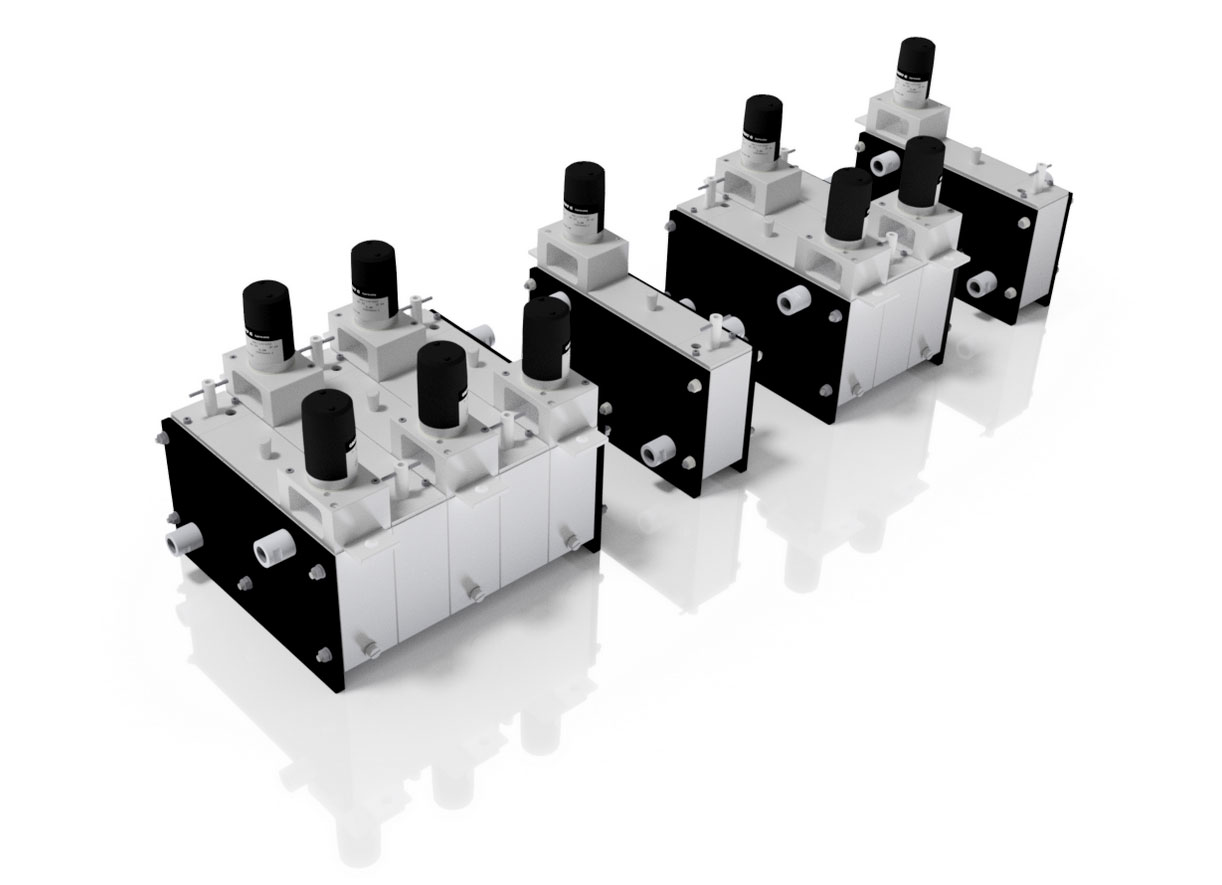

- Validation of hydrometallurgical unit processes and circular flowsheets on mini-pilot scale

- Thermodynamic modelling of hydrometallurgical processes

- Forensic hydrometallurgy

Research philosophy

Guided by our Twelve Principles of Circular Hydrometallurgy, SOLVOMET targets:

- Applied, medium-to-high TRL R and I (EU (Research) Innovation Action projects and bilateral projects with/funded by industry)

- Development of new unit processes and flowsheets that are scalable and industrially realistic

- Insight and understanding of real-world, industrial problems at a molecular level

Equipment

Research Facilities

SOLVOMET

Key metals of interest

Battery Metals

Precious Metals

Base Metals

SOLVOMET

Meet Our Team

More infoGet in touch

SOLVOMET creates innovative solutions for real-world problems.

Work at SOLVOMET

If you are interested in joining our group, please check out our current openings.

Start a project

SOLVOMET performs contract research with industry partners across the world.

services

What we do

How we do it

- We go beyond a basic, trial-and-error methodology to develop or optimise hydrometallurgical flowsheets

- We combine experimental testing on lab/mini-pilot scale with detailed feed characterisation, thermodynamic and kinetic modelling, and a deep, molecular understanding of metal extraction mechanisms

- We build up and maintain stable, long-lasting relationships of trust with key players in the metallurgical industry

Battery Raw Materials

- Ni/Co metallurgy and flowsheeting

- Li metallurgy and flow sheeting

- Competence in Mn SX for battery grade Mn production

- Recovery of other metals (Cu, Zn, Pb, ...). Impurity removal and outlet in all flowsheets (As, Fe, Al, ...)

Thermodynamic modelling

- SOLVOMET can build predictive hydrometallurgical equilibrium models

- SOLVOMET can calculate complex hydrometallurgical systems including multi-phase equilibria and electrolyte solutions

- SOLVOMET can build accurate models (>90% accuracy) with experience in solvent extraction, leaching, and precipitation

Partners

SOLVOMET bilateral projects

Hydro-flowsheet development

Hydro-flowsheet development

Thermodynamic modelling of SX processes

Lithium-flowsheet development (Thacker Pass project, Li-clays)

Lithium-flowsheet development (Salar de Atacama, Li-brines)

Application of bromine technology in urban mining/recycling

Metal recovery from steelmaking sludges

Ag recovery hydro-flowsheet

Application of GTL solvents in hydro-flowsheet

Hydro-flowsheet development

Hydro-flowsheet development (for EoL tyre recycling)

Urban mining /recycling study (REEs)

Developing flowsheets for Sn recovery

Hydro-flowsheet development

Hydro-flowsheet development

Thermodynamic modelling of SX processes

Lithium-flowsheet development (Thacker Pass project, Li-clays)

Lithium-flowsheet development (Salar de Atacama, Li-brines)

Application of bromine technology in urban mining/recycling

Metal recovery from steelmaking sludges

Ag recovery hydro-flowsheet

Application of GTL solvents in hydro-flowsheet

Hydro-flowsheet development

Hydro-flowsheet development (for EoL tyre recycling)

Urban mining /recycling study (REEs)

Developing flowsheets for Sn recovery

What's new