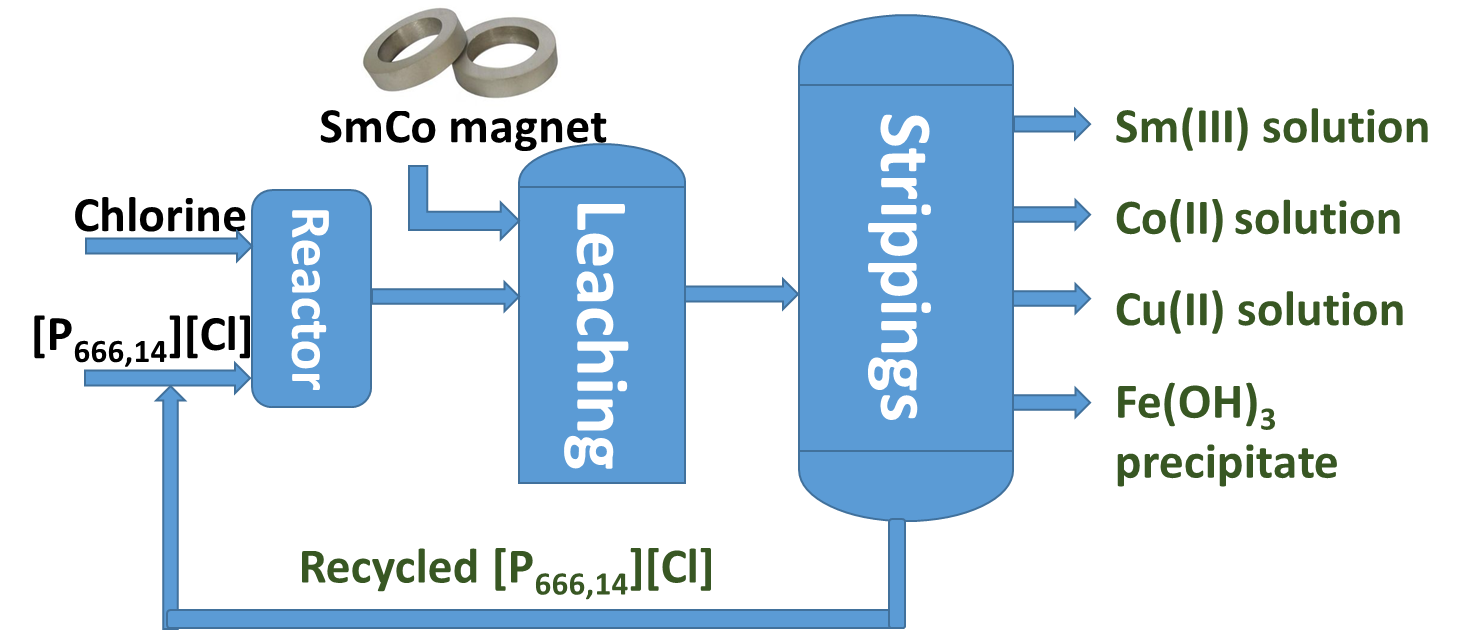

Researchers at SIM² KU Leuven have developed a new method to recover metals from spent samarium-cobalt magnets. The procedure involves oxidative dissolution of these metals in trichloride ionic liquids, followed by metal removal from the leachate with a series of stripping steps. The ionic liquids can be reused for the next cycles after their regeneration. The work is published in the Journal ACS Sustain. Chem. Eng. (PTJ/SL, Leuven 28/1/2019)

SmCo magnets

SmCo magnets are used mainly for high-temperature applications due to their high coercivity (resistance to demagnetisation), good corrosion resistance and excellent thermal stability. the global SmCo magnets market is growing thanks to new applications in consumer electronics, automotive and medical technology, aerospace and military equipment. Recycling of SmCo magnets can lower the supply risk of samarium and cobalt, close the materials loop (circular economy), and reduce the environmental issues associated with primary mining and ore processing.

New method to recover metals from spent SmCo magnets

In this work, a trichloride ionic liquid trihexyltetradecylphosphonium trichloride, [P666,14][Cl3], which can safely store chlorine gas in the form of the trichloride anion, was synthesized and employed as a reactive solvent for the recycling of SmCo magnets. The dissolution efficiency has been studied by varying the volume fraction of [P666,14][Cl3] in [P666,14]Cl (the latter as an additional source of coordinating chloride ions), the solid-to-liquid ratio and the temperature.

Stripping of metals from the loaded IL was studied with different aqueous solutions, followed by a reusability study of the ILs. In the end, a conceptual process flow sheet (Figure 1) was developed for the recovery of metals from SmCo magnet using a trichloride ionic liquid in which single-element aqueous streams are obtained and the IL is recycled.

Oxidative dissolution of metals in trichloride ILs is easily transferable to the recycling of valuable metals from other end-of-life products such as neodymium−iron−boron magnets and nickel metal hydride batteries.

Bio lead author

Xiaohua Li is a postdoctoral researcher working with Prof. Koen Binnemans in the SOLVOMET Group at KU Leuven. She obtained her doctor degree from university of Twente in the Netherlands in February 2017 and started her work on ERC SOLCRIMET project in KU Leuven from November 2016. Her main research interests include separation technology, solvent extraction, leaching, solvometallurgy and ionic liquids.

Xiaohua Li is a postdoctoral researcher working with Prof. Koen Binnemans in the SOLVOMET Group at KU Leuven. She obtained her doctor degree from university of Twente in the Netherlands in February 2017 and started her work on ERC SOLCRIMET project in KU Leuven from November 2016. Her main research interests include separation technology, solvent extraction, leaching, solvometallurgy and ionic liquids.

Full reference paper

Li, X.; Li, Z.; Orefice, M.; Binnemans, K. Metal Recovery from Spent Samarium–Cobalt Magnets Using a Trichloride Ionic Liquid. ACS Sustain. Chem. Eng. 2019, 7 (2), 2578-2584.

Acknowledgements

The research leading to these results received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 Research and Innovation Programme: Grant Agreement 694078 – Solvometallurgy for critical metals (SOLCRIMET) and from the European Community’s Horizon 2020 Programme ([H2020/2014-2019]) under Grant Agreement 674973 (MSCA-ETN DEMETER).