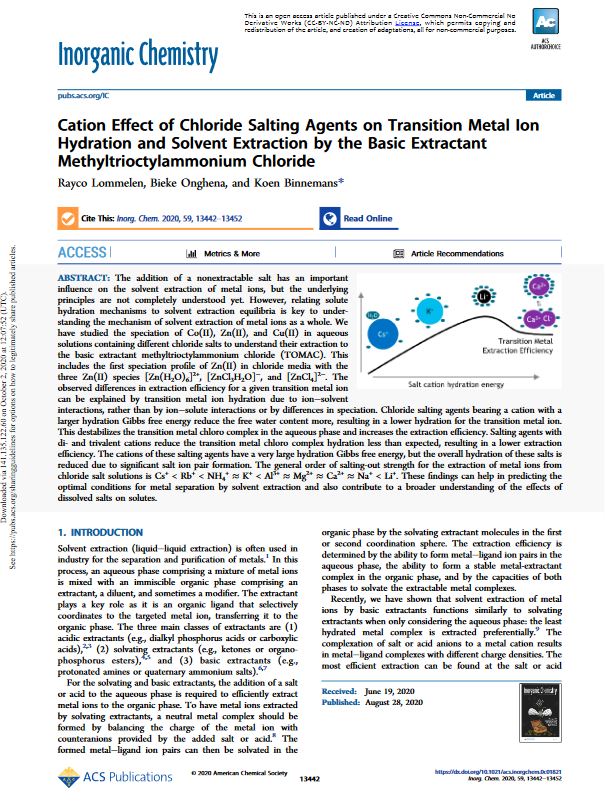

SIM² KU Leuven – SOLVOMET researchers have been able to unravel the effect of dissolved chloride salts on the structure of water and on the complex formation of metal ions with chlorides. These new insights increase the understanding of salt effects on solvent extraction processes of metal ions and can be used to predict better metal separations on both fundamental and industrial level. The work has been published in the journal Inorganic Chemistry.

Solvent extraction

Solvent extraction is often applied to separate and purify key metals such as cobalt and nickel, which are essential for clean energy and mobility applications (e.g Li-ion NMC batteries). In this technique, a feed solution with a mixture of metals is brought in contact with an organic phase that contains at least an extractant. The extractant selectively coordinates with some of the metals and facilitates their transfer to the organic phase, hence allowing to separate metals.

When neutral or basic extractants are used, a salt or acid should be added that supplies anions to the metal feed. These anions will bind with some metal ions to create extractable metal complexes. Although the effect of different anions on the extraction of metal ions is already quite well understood, the choice of the salt cation has a major impact on the extraction behavior and can, as a result, be used to finetune an extraction process.

Understanding water

The transfer of a metal complex from an aqueous to an organic phase is a balancing act. In the organic phase, the extractant molecules surround the metal complex and try to keep the metal complex there.

In the aqueous phase, the metal complex is stabilised by water molecules. More water molecules surrounding a metal complex results in a stronger stabilisation. The balance between these two forces determines the extraction of a metal complex.

The extraction of a metal can be increased by reducing the amount of water molecules that surround the metal complex. This can be accomplished by lowering the charge of the metal complex and by lowering the amount of free water molecules in the system.

The charge of a metal ion can be lowered by supplying anions that bind to that metal cation. For instance, by suppling chlorides that bind to cobalt(II). These anions are introduced by adding a salt or acid to the aqueous phase, but this also introduces cations to the system.

Small and/or highly charged cations like to be surrounded by a lot of water molecules. This lowers the amount of free water that can surround the extractable metal complexes and thus increases extraction. On the other hand, bulky cations with a low charge do not attract the water molecules as much. This leaves a lot of water available to surround the extractable metal complex.

Practical applications

These new insights allow hydrometallurgical researchers and industrialists to select the optimal salt or acid for their metal separation process based on solvent extraction.

The direct link between salts and water also should allow the construction of broadly applicable thermodynamic models, based on the activity of water in different salts. These models can be used to calculate solvent extraction processes and reduce the time and number of experiments necessary to design or improve a flowsheet.

Lommelen, R.; Onghena, B.; Binnemans, K. Cation Effect of Chloride Salting Agents on Transition Metal Ion Hydration and Solvent Extraction by the Basic Extractant Methyltrioctylammonium Chloride. Inorg. Chem. 2020, 59 (18), 13442–13452. https://doi.org/10.1021/acs.inorgchem.0c01821.

Acknowledgements

The authors thank the FWO Flanders (projects G0B6918N and I000718N) and the European Research Council (European Union’s Horizon 2020 Research and Innovation Programme: Grant Agreement 694078) for financial support. The contents of this publication are the sole responsibility of the authors and do not necessarily reflect the opinion of the European Union.

SOLVOMET/SIM² KU Leuven?

- General SOLVOMET Group website: https://chem.kuleuven.be/solvomet

- Lab facilities: https://solvomet.eu//mini-pilot-scale-equipment-2/

SOLVOMET Group Photo