In May 2020, SOLVOMET filed the patent application “Method for producing battery grade lithium hydroxide monohydrate” (priority date: 2020-05-13). The patent application (WO2021228936A1, Prof. Koen Binnemans) became public in November 2021. The first part of the patented flowsheet, involving a one-step (solvometallurgical) process to purify technical-grade lithium chloride into battery-grade quality, was disclosed in June 2022 through a first paper in Journal of Sustainable Metallurgy. The second part of the patented flowsheet, which allows to obtain the coveted battery-grade lithium hydroxide monohydrate (LiOH·H2O) through a unique double solvent extraction process, was then disclosed through another paper in Journal of Sustainable Metallurgy in December 2022. One weakness of the process was the uptake of CO2 from the atmosphere; this problem has now been solved by designing the process with the help of an agitated extraction column.

SOLVOMET’s LiCl to LiOH conversion process

In SOLVOMET’s previously reported work, the LiCl to LiOH conversion process was successfully upscaled in mixer-settlers. However, a minor drawback was that up to 7% of the end product was converted into lithium carbonate by CO2 uptake from the air.

In order to mitigate this problem, the SOLVOMET team decided to develop a process in a more enclosed contactor type, namely an agitated Kühni extraction column. This work has now been successfully completed. No conversion of lithium hydroxide into lithium carbonate was detected at the end of the process, leading to a final product of >99.95% purity. The work has now been disclosed through a paper in the Journal of Sustainable Metallurgy in April 2024. This publication was made possible by the Era-Min 3 project ACROBAT, that obtains battery-grade lithium chloride via a HCl-based hydrometallurgical recovery route from spent lithium-iron-phosphate batteries.

LiCl to LiOH conversion in an extraction column

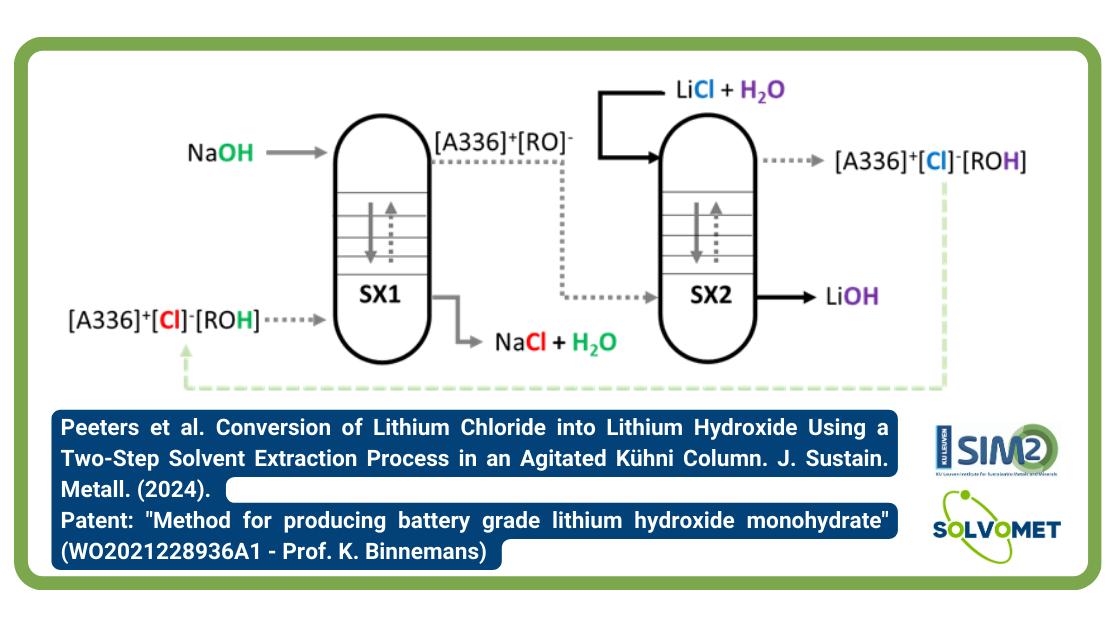

The article uses an organic phase consisting of the quaternary ammonium salts Aliquat 336 ([A336] [Cl]−) and a commercially available phenol (butylhydroxytoluene) that is contacted with 2 mol L−1 NaOH. This initial SX step (SX1) deprotonates the phenol and transfers the chloride anion of [A336] [Cl]− to the aqueous phase. After extraction, NaOH is converted into NaCl in the aqueous phase and the cation of [A336] recombines with the anionic phenolate in the organic phase. The latter phase is then contacted with 1.6 mol L−1 of battery-grade LiCl in the subsequent step (SX2). The phenolate in the organic phase gets then re-protonated by water, forming OH− in the aqueous phase. The Cl− counter-anion of LiCl is then transferred to the organic phase to maintain the electric neutrality.

Thus, after extraction, [A336] [Cl]− and the phenol in the organic phase are regenerated for the subsequent cycle and Li combines with OH− in the aqueous phase. 75 L of lithium chloride was processed through an agitated Kühni extraction column with five column heights, resulting in 96% conversion into lithium hydroxide with a purity of 99.95% or higher. Our two-step conversion process is now ready to be further exploited with respect to other industrial sources of lithium chloride, like for example brines.

Full reference papers

- Nand Peeters, Sofia Riaño, Koen Binnemans, Conversion of Lithium Chloride into Lithium Hydroxide Using a Two-Step Solvent Extraction Process in an Agitated Kühni Column. Journal of Sustainable Metallurgy (2024). https://doi.org/10.1007/s40831-024-00815-4

- Dženita Avdibegović, Viet Tu Nguyen, Koen Binnemans “One‑Step Solvometallurgical Process for Purification of Lithium Chloride to Battery Grade”, Journal of Sustainable Metallurgy, 2022, 8, 893–899. doi.org/10.1007/s40831-022-00540-w (Open Access paper).

- Viet Tu Nguyen, Clio Deferm, Ward Caytan, Sofía Riaño, Peter Tom Jones, Koen Binnemans, “Conversion of Lithium Chloride into Lithium Hydroxide by Solvent Extraction”, Journal of Sustainable Metallurgy, https://doi.org/10.1007/s40831-022-00629-2 (Open Access paper).

Patent application “Method for producing battery grade lithium hydroxide monohydrate”

Patent application WO2021228936A1: Method for producing battery grade lithium hydroxide monohydrate: Priority 2020-05-13, Filed 2021-05-12, Published 2021-11-18: https://patents.google.com/patent/WO2021228936A1/en). Companies that are interested in this patent application can contact Dr. Peter Tom Jones, Industrial Research Fund Valorisation Manager for the SOLVOMET KU Leuven Research Group, through his LinkedIn profile.

Acknowledgements

This research has received funding from the Research Foundation Flanders (FWO) under Grant Agreement S008621N as part of ERA-NET Cofund on Raw Materials (ERA-MIN3) under the European Union’s Framework Programme for Research and Innovation H2020 in the project ACROBAT—Advance Critical Raw Materials Recycling From Spent LFP Batteries.