SOLVOMET/SIM2 KU Leuven researchers have developed three different routes to recover and purify Pd, Pt and Rh from spent autocatalysts. One of these routes (liquid-liquid extraction) was selected for industrial validation together with two other technologies developed by the colleagues from VITO. Within the framework of the EU PLATIRUS project, the combination of these technologies allowed the recovery of high-purity PGMs that were used in the fabrication of new catalysts. The other routes developed by SOLVOMET/SIM2 KU Leuven comprise the use of concentrated solutions of FeCl3 in acetonitrile for leaching followed by non-aqueous solvent extraction; and the use of highly concentrated solutions of AlCl3·6H2O and Al(NO3)3·9H2O for selective dissolution of the PGMs. All the technologies developed in this project have been summarised and published in the journal Johnson Matthey Technology Review.

The PLATIRUS project

PLATInum group metals Recovery Using Secondary raw materials (PLATIRUS), a European Union (EU) Horizon 2020 project, aims to develop greener recycling processes that allow the recovery of platinum group metals (PGMs).

Different technologies, such as ionometallurgical leaching, microwave assisted leaching, solvometallurgical leaching, liquid separation, solid phase separation, electrodeposition, gas-diffusion electrocrystallisation and selective chlorination have been developed and evaluated and the best technologies have been coupled into a PLATIRUS flowsheet comprising microwave assisted leaching, liquid-liquid extraction and gas-diffusion electrocrystallisation.

Operating in cascade, the PLATIRUS flowsheet allowed the recovery of Pt, Pd and Rh from spent autocatalysts and their use in the production of new autocatalysts for validation by end users.

The role of SOLVOMET: liquid-liquid extraction

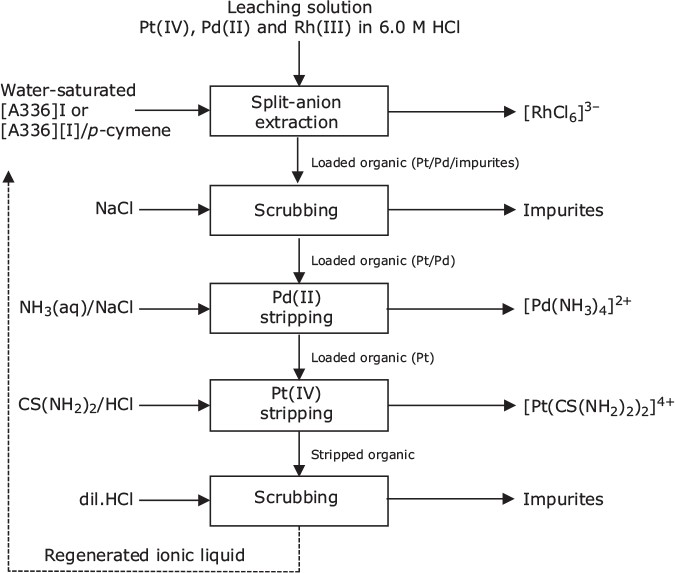

A split-anion solvent extraction process was developed for the recovery and separation of PGMs from a complex aqueous mixture of metals. While leaving Rh in the raffinate, Pd and Pt were extracted from the chloride leaching solution using the iodide form of the quaternary ammonium IL Aliquat® 336, [A336][I], dissolved in p-cymene. Different stripping agents were used to recover the individual PGMs from the loaded organic phase.

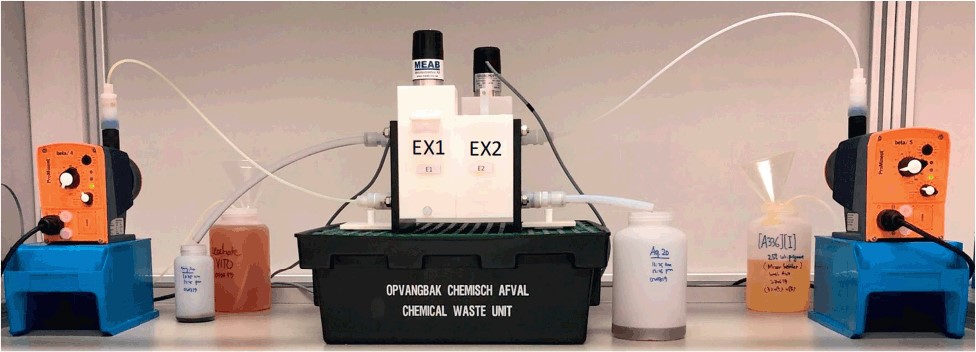

The liquid-liquid extraction flowsheet is presented in figure 1. During two months, the process was validated at the SOLVOMET/SIM² KU Leuven facilities using 10 mixer-settler stages for extraction, scrubbing and stripping. The extraction step is presented in figure 2.

Figure 1. SOLVOMET/ SIM2 KU Leuven proposed flowsheet for the extraction and separation of PGMs from spent autocatalysts

Figure 2. Extraction of pgms from leachate of spent autocatalyst in two-stage mixer-settlers at SOLVOMET/ SIM2 KU Leuven

The other technologies developed by SOLVOMET

In parallel to the liquid-liquid extraction process that was scaled up in KU Leuven’s mini-pilot facilities, two solvometallurgical processes were developed. In the first one, the PGMs were leached using FeCl3 or CuCl2 as oxidsing agents in organic solvents such as dimethyl sulfoxide or acetonitrile. Varying the process conditions allowed to recover Pd or Pt/Rh selectively.

This work has been recently published in the journal ACS Sustainable Chemistry and Engineering. The other technology consists of the use of highly concentrated solutions of AlCl3·6H2O and Al(NO3)3·9H2O which allow the selective dissolution of Pd from spent autocatalysts. This work has been recently published in Chemical Communications and the story about where this idea came from can be found here.

These three processes have in common that they are a much environmentally friendlier alternative to the conventional use of aqua regia or harsh conditions for the dissolution of these metals.

Full reference paper

This paper summarises all key achievements in the EU PLATIRUS project, including those of VITO, Tecnalia, SINTEF, VUT and several other project partners:

Nicol, Giovanna; Goosey, Emma; Yıldız, Deniz Şanlı; Loving, Elaine; Nguyen, Viet Tu; Riaño, Sofía ; Yakoumis, Iakovos ; Martinez, Ana Maria; Siriwardana, Amal; Unzurrunzaga, Ainhoa; Spooren, Jeroen; Atia, Thomas Abo; Michielsen, Bart; Dominguez-Benetton, Xochitl; Lanaridi, Olga; Platinum Group Metals Recovery Using Secondary Raw Materials (PLATIRUS): Project Overview with a Focus on Processing Spent Autocatalyst : Novel pgm recycling technologies ready for demonstration at next scale, Johnson Matthey Technology Review, 65 (1), 127-147 (2021). doi: 10.1595/205651321×16057842276133 – https://www.technology.matthey.com/article/65/1/127-147/

Acknowledgements

The PLATIRUS project has received funding from the European Union’s Horizon 2020 Research and Innovation programme under Grant Agreement n° 730224.